|

Among the big family of decoration materials, artificial marble is a "star" member that has attracted much attention.

Today, I will talk about artificial marble.

The birth of artificial marble

The history of artificial marble can be traced back to 1948 when Italy first began producing cement-based marble tiles, marking the beginning of artificial marble. In 1958, the United States used resin as a binder to manufacture panels that simulated the natural marble texture.

By the late 1960s to early 1970s, artificial marble rapidly developed in multiple countries, and China introduced relevant technology and equipment at the end of the 1970s, entering a period of rapid development in the 1980s.

The true face of artificial marble

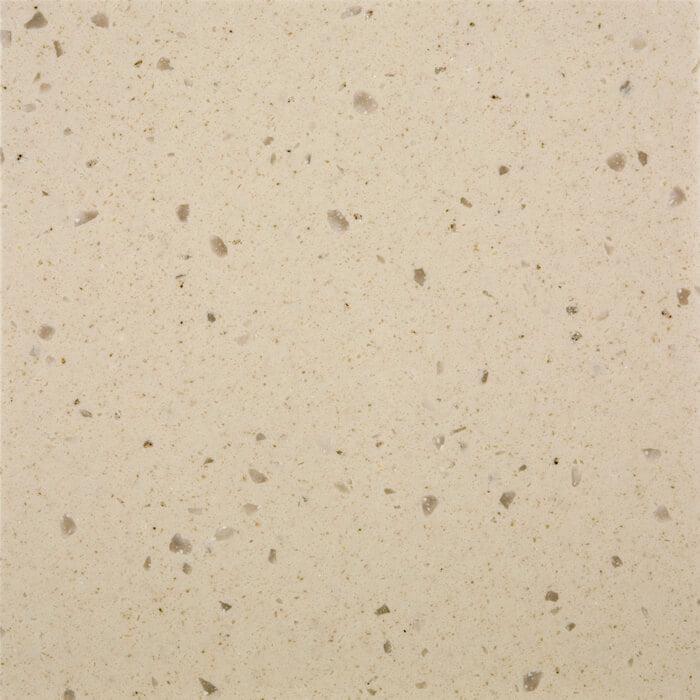

Artificial marble is mainly composed of fillers, binders, and additives.

Fillers are generally selected from granite chips or natural marble chips, while binders are often cement, gypsum, and unsaturated polyester resins, along with inorganic materials such as dolomite, glass powder, and silica sand, as well as pigments and other additives. After a series of processes including mixing, forming, grinding, and polishing, the artificial marble is produced.

The "superiority" of artificial marble

Rich appearance selection: The patterns and colors of artificial marble are extremely rich, which can be customized according to different decoration styles and personal preferences. It can perfectly simulate the texture of various natural marble, and even create unique patterns to meet personalized decoration needs.

Superior physical properties: its strength is high, the flexural strength is much higher than that of natural marble, and the water absorption rate is low, the stability is good, has strong corrosion resistance and anti-pollution ability, not easy to be affected by the external environment, long service life.

Environmental and Health: During the production process, physical and chemical treatments are applied to remove harmful substances such as sulfides and salts from natural stone materials, making it a green and environmentally friendly building material.

Moreover, artificial marble does not emit radiation like natural marble, posing no health risks to humans.

Convenient processing: The manufacturing process is relatively simple, raw materials are easily obtainable, production efficiency is high, and products can be made in various shapes and sizes such as sheets, irregular shapes, sanitary ware, etc. They can also undergo cutting, drilling, splicing, and other processing. The construction difficulty is low, installation efficiency is high, and it can effectively shorten the renovation cycle.

The "small flaw" of artificial marble

Relatively low hardness: Compared with natural marble, artificial marble is slightly less hard and easy to scratch. In daily use, it is necessary to avoid contact with sharp objects.

Limited heat resistance: If exposed to high temperature for a long time, artificial marble may have problems such as discoloration and deformation, so it should be avoided to put hot pots, hot bowls and other things directly on its surface.

Quality difference: The quality of artificial marble brands and products on the market is uneven. If you buy a poor quality product, you may have problems such as uneven surface, uneven color and easy cracking.

The "use of artificial marble"

Architectural Decoration: In the field of construction, artificial marble is widely used for decorating walls, floors, columns, staircases, and other areas, enhancing the overall aesthetics and class of buildings.

Its lightweight characteristic also facilitates transportation and construction, making it particularly suitable for high-rise buildings and large public buildings.

Home Decoration: Kitchen countertops bathroom sinks bathroom walls and floors are all common application scenarios for artificial marble.

Its waterproof stain-resistant and easy-to-clean properties make it very suitable for these damp and dirty environments while also adding an element of elegance and fashion to the home.

Industrial field: artificial marble can also be used to make some basic components and work surfaces of industrial equipment. By using its excellent physical and mechanical properties and chemical stability, it can improve the service life and stability of the equipment.

Artificial marble, with its numerous advantages, occupies an important position in the decorative materials market.

Of course, when choosing and using it, we must also fully understand its characteristics and select products that are reliable in quality and suitable for our needs based on actual requirements and budget, allowing artificial marble to add more charm and comfort to our living and working spaces.

|